sand gravity separation

Pre-wetting of sand for high speed oil-water separation

2022.12.1 In the present study, a high speed gravity-driven oil–water separation method has been realized by using pre-wetting of river sand, sea sand, and desert sand. The superoleophobicity properties of these pre-wetted sand materials have been found

More

Gravity Separation - SGS

2022.6.21 10-2013 GRAVITY SEPARATION WHY USE GRAVITY SEPARATION? Gravity separation is the most well-proven and accepted technique of concentrating

More

Underoil superhydrophilic desert sand layer for

It is worth mentioning that the sand layer could serve as an adsorbent material with under-oil superhydrophilicity, achieving ultrafast gravity

More

(PDF) Gravity Separation: Old Technique/New

2003.3.1 PDF A comparative review of various types of the main gravity separation devices, both in the recent past and present is

More

(PDF) Gravity Separation of Silica Sands for Value Addition

2013.5.1 Hagras (2013) showed that gravity separation is suitable for purifying silica sands as a result of the removal of heavy minerals. Ibrahim et al. 2013 ) purified a white

More

沙漠也有用:油下超亲水沙层能快速实现油包水乳液的

2017.12.27 沙漠也有用:油下超亲水沙层能快速实现油包水乳液的高效分离. 材料. 作者:X-MOL 2017-12-27. 随着工业含油废水的排放和溢油事故的频繁发生,油水混合物的分离越来越受到社会的广泛关注。. 传统的

More

Gravity separation by falcon concentrator- an over review

2022.1.20 In terms of performance, separation efficiency, and processing of finer feed particle size ranges, this method outperforms standard gravity-based separation. Falcon

More

Minerals Free Full-Text The Possibility of

2022.5.24 The majority of beneficiation of sands or aggregates starts with a gravity separation to separate heavy minerals from gangue, which is mostly quartz [13,14,15]. Comminution is usually not required for these

More

Technological developments in processing

The heavy minerals in the mined sand are processed by gravity separation processes or flotation to yield a heavy mineral concentrate (HMC), and then the valuable minerals are separated in a mineral separation plant (MSP)

More

Process development to recover rare earth metals from monazite

2015.8.1 Beneficiation of monazite from beach sand mineral, involves gravity separation along with magnetic separators to eliminate strongly magnetic minerals such as magnetite and are also used to separate paramagnetic monazite from non-magnetic heavy mineral gangue material such as zircon and rutile (Ferron et al., 1991, Jordens et al.,

More

Mechanisms and kinetics of gravity separation of

5. Analysis of predictive properties of the experimental analytical method for the study of gravity-driven flow parameters 553 6. Analysis of separation mechanisms and kinetics based on results of mathematical and physical simulation 554 7. Summary. Conclusion 558 References 560 1 The term granular matter is commonly used in the English-language

More

(PDF) Gravity Separation: Old Technique/New

2003.3.1 Gravity separation is therefore considered a traditional physical beneficiation for most (heavy) minerals [7,18]; employing the use of sluices, shake tables, jigs, air floaters, heavy/dense media ...

More

Process Mineralogy for the Development of a Flowsheet to

2023.5.21 Monazite minerals can be found in traces in the sand placer deposits all along the coast of different continents of the earth. The global occurrence of monazite (5) is shown in Fig. 3.It is seen from Fig. 3 that monazite mineral is found all along the coastal tracts of Brazil, India, Ceylon [Sri Lanka], Burma, Korea, Taiwan, Indonesia, Malaysia,

More

How To Extract Gold From Sand? - Mining-pedia

2020.4.23 In gold sand gravity separation, when roughing with a chute or jig, the coarse concentrate is usually enriched by a shaker with a very high ore ratio, its recovery rate can reach more than 98%, and directly get the final concentrate and abandoned tailings. The above process is generally used in small-scale, low-grade gold sand concentrators.

More

Physical beneficiation of heavy minerals - ScienceDirect

2023.8.1 The efficiency of physical separation techniques of heavy minerals usually encounters some set-backs. The reason is often not far from the inability to develop suitable mineral characterization strategies in order to comprehend/evaluate certain physicochemical features such as surface chemistry, specific gravity difference, magnetic and electrical

More

Gravimetric Separation of Heavy Minerals in Sediments and

2020.3.18 The potential of heavy minerals studies in provenance analysis can be enhanced conspicuously by using a state-of-the-art protocol for sample preparation in the laboratory, which represents the first fundamental step of any geological research. The classical method of gravimetric separation is based on the properties of detrital minerals,

More

The separation of oily water using low-cost natural materials: Review ...

2021.12.1 Experimental results revealed that natural sand filtration is a promising technology with the characteristics of: 1) a surface of superhydrophilicity and underwater superoleophobicity; 2) sands bed achieved separation efficiency and flux comparable or higher than commercial microfiltration membranes under natural gravity conditions, and

More

Minerals Free Full-Text Heavy Mineral Sands Mining and

2021.11.11 Heavy mineral sands are the source of various commodities such as white titanium dioxide pigment and titanium metal. The three case studies in this paper show the value of X-ray diffraction (XRD) and statistical methods such as data clustering for process optimization and quality control during heavy mineral processing. The potential

More

7 Methods and Equipment for Removing Iron

2023.2.15 The following introduces 7 methods and equipment for removing iron from quartz sand. Quartz sand 1. Gravity separation method Gravity separation can usually be used effectively for the entire particle

More

Subsea Processing System Advisory - Eagle

6 天之前 Separation system GLCC SSAO Hybrid Scrubber Technology Caisson with ESP Pipe separator and hydrocyclone Veritcal gravity and cyclonic separator Compact vertical vessel with inlet swirl Purpose Gas/Liquid Gas/Oil/Water/Sand Gas/Liquid Condensate/Gas Manufacturer FMC FMC FMC Aker Solutions Water depth, m 2500 870 800 300 Tie

More

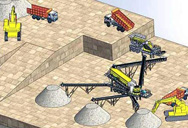

Gravity Separation Equipment - JXSC Machinery

2 天之前 Gravity separation is an important mineral processing recovery method. According to the difference in density between minerals, the gravity, fluid power, or mechanical force in the moving medium is different, and

More

Minerals Free Full-Text Concentration and Recovery of Valuable ...

2020.11.30 Most of the mineral processing involving sand begins with gravity separation [10,14,16,23] owing to the density difference with the gangue (mostly quartz). Moreover, any physical beneficiation, which includes sands and placer deposits for concentrating heavy minerals, needs to have the capability to treat big amounts of the

More

Development of Flow Sheets to Recover Critical Minerals

2023.7.15 The present investigation deals with a novel approach to recovering individual critical industrial minerals from a new lean-grade beach sand deposit in Bramhagiri, Odisha, India. This sand deposit contains 3.43% ilmenite, 0.16% rutile, 0.82% garnet, 0.87% zircon, 0.11% sillimanite and 0.01% other heavy minerals. Spiral

More

Research on Sand-dust Separation Technology Based on

The gas-solid two-phase numerical simulation method is adopted, and the possible cyclone separation, inertial separation methods are used to study the separation efficiency. and regularity technology, which provides a basis for the separation design and test of the sand-dust. environment simulation of large electromechanical products.

More

Liquid–Solid Separation: De-Sanding—Flocculation

2022.1.23 The rake classifier is a combination of a classification trough for gravity separation of the coarse sand fraction in the feed slurry and a reciprocating rake for continuously discharging the settled sand from the unit. The feed slurry enters the classification trough through a feed device which provides an equal distribution of the

More

Gravity Separation - ScienceDirect

2016.1.1 By the 1950s, spirals were the standard primary wet gravity separation unit in the Australian mineral sands industry. In the spiral concentrator the length of the sluicing surface required to bring about segregation of light from heavy minerals is compressed into a smaller floor space by taking a curved trough and forming into a spiral about a ...

More

Gravity Separation SpringerLink

2022.2.28 Gravity separation is a method in which materials/minerals are separated based upon the difference in particles density [].Water as a medium is an important factor in improving the differential movement between various particles during gravity separation and eventually sorting different particles [].When water is removed, and air plays the role of

More

Spiral (Concentrators) - an overview ScienceDirect Topics

15.5.3 Spiral Concentrator. The spiral concentrator first appeared as a production unit in 1943 in the form of the Humphrey Spiral, for the separation of chrome-bearing sands in Oregon. By the 1950’s, spirals were the standard primary wet gravity separation unit in the Australian mineral sands industry.

More

(PDF) Technological developments in processing

2020.2.1 Further enhancement of gravity separation has been achieved using the Kelsey Centrifugal Jig (KCJ), which also operates in a multi-g environment, but separates minerals on the basis of specifi c ...

More

Filtration and separation technology: What's new in

2009.1.1 This is coupled with separation by a screen or sieve, which is largely gravity driven, and separation in a deep bed (or sand) filter, where, again, the driving force is often that of gravity. The full range of equipment types to be covered therefore is as follows, although not all will have noteworthy developments: •

More

Methods of Separation of Mixtures with Examples - Scienly

2023.1.11 Some mixtures that the magnetic separation method can separate are: Separation of iron ore from sand. Iron fillings from sulphur. Gravity Separation. We use this process for the separation of a mixture having components of different densities. The powdered mixture undergoes with a stream of running water.

More

Water Separation Performance in Bitumen Recovery from

The oil (diluted bitumen)–water separation efficiency at steam-assisted gravity drainage (SAGD) process conditions has been evaluated in a laboratory environment by using a custom-built batch gravity setup, using SAGD field fluids and commercial gas condensate as a diluent. The key parameters and conditions investigated are solvent amount, shear

More

Physics in the oil sands of Alberta Physics Today AIP

2009.3.1 The oil-sands lumps are crushed, mixed with warm water and chemicals, and then introduced into a hydrotransport pipeline. Turbulence in the pipeline liberates the bitumen droplets from solid particles and the droplets become aerated. The flowing slurry is introduced into a large gravity-separation vessel, where the aerated bitumen floats to the ...

More

Gravity Separators – Visual Encyclopedia of Chemical

General Information. Gravity separators, or air tables, separate particles with very close specific gravities. The particles are fed onto a large, slotted deck that is tilted slightly, as shown here. The deck vibrates and fans force air upward. Denser particles travel to the high side of the deck, while lighter particles roll off the low side.

More

CTB3365x Introduction to Water Treatment - edX

2015.7.8 0.4 m/s to prevent that sand settles in the screens . In the grit removal device, we lower the liquid velocity a bit further to make use of gravity separation to settle the sand . Gravity separation, or settling or sedimentation, is one of the most common approaches to pre -treat, or partially treat, the domestic and municipal sewage flows .

More

A new method for gravity separation: Vibrating table gravity ...

2019.3.18 A gravity concentrator namely “vibrating table” has been developed with the objective of increasing the product quality of density based physical separation processes. The system is mainly composed of a vibration unit, an inclined chute, TW and WW jets. The principle idea of the separation is to combine the involved forces of a

More

Sand settling in a three-phase flow inside a horizontal

2022.11.1 Horizontal separators have proven to be one of the most effective methods for sand removal especially the design developed by Specialized Desanders Inc., this study will analyze the sand separation in a three-phase flow from two angles. First, by applying multiphase numerical analysis using Star CCM+ software.

More

Optimization of a primary gravity separation treatment for

2014.4.11 Vegetable oil refinery wastewaters (VORW) are loaded with organic and oily matter, and cannot be decontaminated by conventional treatment methods. Pretreatment methods with the objective of decreasing oil and grease (OG) and chemical oxygen demand (COD) content either generate hazardous byproducts or may be too

MoreArticle aléatoire

- inching balle entrainement moulin

- impact sur les importateurs de Belgique de concassage

- la poussière des broyeurs à marteaux contror

- broyage des herbes sèchées aromatiques

- Machine de broyage de poudre portatif

- broyage de roche de portland

- Kefid minning et les travaux de construction

- le minerai de fer concassage et de tamisage

- broyage de la canne a sucre pdf

- pdf concasseur à marteaux

- équipement de broyage de sel gemme

- or dans le minerai de fer

- protable concasseur de roche de l'australie

- la planta de sinterización de manganeso se fabrica en la india

- construit votre propre concasseur de roche

- videos de molino de manuelita

- Indonésie propos de broyage balle des médias

- quelle est la fonction de la machine de pulverisation

- concasseur dmasse volumique de fer

- broyeur de pierres mapan

- moulin a vent en bouteille plastique

- delear concasseur en Nouvelle Caldonia

- ppt de lit fluidisé triphasé

- 60 pouces à double broyeur à deux cylindres

- usines de concassage portables nw occasion

- Méthodes De Bénificiation Du Minerai De Fer

- broyeurs a marteaux utilises pour lindustrie de blocs de beton

- fabrication de four rotatifmines de calcaire

- poudre de craie fabricant rouleau broyeur

- pièces de rechange pour machine de fabrication de blocs

- avantages et les inconvénients de concasseur à machoires concasseur giratoire à

- concasseur à cône indiadirectory concasseur machines

- charbon moulin problème de démarrage

- liste de la plante concasseur à haryana

- equipement de securite de la machine concasseur

- concassage et criblage dusines en calcaire