cement mill plant design drawings

Nomograms for Design and Operation of Cement Plants

2013.9.21 Feasibility, Construction, Electrical and Instrumentation in Cement Plants. SALIENT FEATURES ♦ Comprehensive coverage of all aspects of Cement plant

More

PROCESS ENGINEERING FOR THE CEMENT LIME

2020.10.6 process engineering for the cement lime industries mechanical engineering (plant design, piping, process gas handling, environmental controls,

More

Industrial plants - factories on AutoCAD 765 free

765 Industrial plants - factories CAD blocks for free download DWG AutoCAD, RVT Revit, SKP Sketchup and other CAD software.

More

2. Raw Mill-Hoppers (Cement Plant) files - GrabCAD

2013.3.7 This is the 3D Auto cad drawing. This is the second department in the Cement Plant. All related unit foundation drawings are made available ... - files

More

Advanced Plant Engineering Solutions Expertise in

5 天之前 Design, development, and detail engineering including as built drawings for challenging structures like cement mill feed house with heavy hoppers with total capacity

More

Cement Plant 3D CAD Model Library GrabCAD

Cement Plant 3D CAD Model Library GrabCAD. Join 13,040,000 engineers with over 5,970,000 free CAD files Join the Community. The CAD files and renderings posted to

More

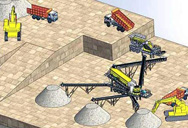

The example of the horizontal cement mill layout

One of the basic arrangement of the drive of a horizontal cement mill is shown in Figure 1. -with shift (left, right) of the electric motor axis related to the mill axis: a) drive with

More

Cement Mill Cement Ball Mill Vertical Cement

In general, cement mill can both apply for dry cement production and wet cement production. Commonly, there are three hot types of cement mill in the cement industry: cement ball mill, Raymond mill, and vertical cement

More

8 Tips For Cement Plant Design Cement Manufacturing

2023.11.1 The design of the cement grinding system is also focused on “energy saving”, because the cement grinding part accounts for about 45% of the electricity consumption in the cement plant. There are many cement grinding system processes to choose from, including open flow grinding, ordinary closed circuit grinding, pre-grinding,

More

VERTICAL ROLLER MILLS A holistic VRM approach

2022.4.4 2 VERTICAL ROLLER MILLS INTERNATIONAL CEMENT REVIEW SEPTEMBER 2021 played by the mill foundation, which has been optimised to reduce vibrations.2 Built to last The mill foundation, ie, the basic block with its four concrete pylons, is responsible for the smooth running of the mill. The roller units and mill housing are not

More

OK™ cement mill The most energy- efficient mill for

2019.4.10 OK™ cement mill - FLSmidthIf you are looking for a reliable and efficient cement grinding solution, you may want to consider the OK™ cement mill. This brochure introduces you to the features and benefits of this vertical roller mill, which can handle a wide range of cement types and capacities. Learn how the OK™ cement mill can help you

More

Cement Plant 3D CAD Model Library GrabCAD

The Computer-Aided Design ("CAD") files and all associated content posted to this website are created, uploaded, managed and owned by third-party users. Each CAD and any associated text, image or data is in no way sponsored by or affiliated with any company, organization or real-world item, product, or good it may purport to portray.

More

PROCESS CONTROL FOR CEMENT GRINDING IN

2017.10.27 The power ingesting of a grinding process is 50-60% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 30-40% associated with other grinding mills. The process variables in cement grinding process using VRM are strongly nonlinear and

More

quadropol® - thyssenkrupp Polysius

Cementos Cibao S.A., cement producer in the Dominican Republic, continues the modernization process and ordered a cement mill type QMC² 40/20 for grinding different cement types. Compact plant arrangement with service tower, quadropol® vertical roller mill and main filter are part of the supply. Optimized mill operation will be supported by a ...

More

The layout of the coal mill with a rotary classifier. Download ...

VRM has been widely researched in processing of cement (Ito et al. 1997;Jorgensen 2005;Wang et al. 2009, Ghalandari et al. 2021), coal (Tontu 2020), iron ore (Reichert et al. 2015), zinc ore (van ...

More

Cement Euipment Overview Cement Making Machines Cement Plant

2019.9.27 AGICO offers cement making machines including cement mill, rotary kiln, cement crusher, cyclone preheater, cement dryer, clinker cooler etc. any need? Skip to content +86 13683722138 ... and your drawings with details, you can send the drawing to info@cement-plants. Detailed information is greatly helpful for us to give you the

More

(PDF) Cements ground in the vertical roller mill fulfil the

2013.3.1 This study investigated a mathematical model for an industrial-scale vertical roller mill(VRM) at the Ilam Cement Plant in Iran. The model was calibrated using the initial survey's data, and the ...

More

list of cement plants in madhya pradesh

\n \n HI BOND CEMENT,Cement Manufacturer, \n. HI BOND Cement supplies best quality cement in India.We supply OPC Cement,53 Grade Cement,PPC Cement with high strength.Call us for OPC Cement,PPC Cement mini cement plant andhra pradesh list grinding mill chinalist of cement plants in bhutan Grinding Mill China,Top Cement

More

Cement Products Canada Mortar Masonry Cement Lafarge

3 天之前 Our aim is to produce high-performance cements with significantly reduced carbon footprints, leading the way in building more eco-conscious communities. Our dedication to sustainability doesn't stop at our specialty products. Masonry cement, mortar cement, and blended cement–each product in our broad portfolio carries our commitment.

More

EVERY COMPONENT OF BALL MILL DETAILED

1.Axial/radial runout. 2.Alignment of the drive trains. 3.Uneven power splitting. 4.Centre distances variable. 5.Face load distribution. 6.Sealing of the girth gear. 7.Girth gear is through hardened only, fatigue strength is

More

sbmchina/sbm 3.8 m cement mill drawing.md at main

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

More

cement factory drawing and design Stone Crusher

cement plant autocad drawing templates free – Grinding Mill China. design software Bentley Plant PID. Contact the manufacturer directly 9788178001456, 8178001454 Handbook for Designing Cement

More

sbm/sbm cement milling drawing.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

More

Cement Mill Cement Ball Mill Vertical Cement Mill AGICO

Cement mill in cement plant. Cement mill is the core equipment for grinding material after clinker production. ... our services cover design, equipment supply, project construction, installation ... material and weight, and your drawings with details, you can send the drawing to info@cement-plants. Detailed information is greatly helpful ...

More

Schematic of ball mill circuit in the Ilam cement plant.

This study investigated a mathematical model for an industrial-scale vertical roller mill(VRM) at the Ilam Cement Plant in Iran. The model was calibrated using the initial survey's data, and the ...

More

Cement Production Process Cement Manufacturing ... - AGICO Cement Plant

2020.8.25 There are three steps of the high-temperature system: Drying or preheating, calcining, and sintering. The calcining is the core part of the clinker production; the raw meal is weighed and sent into preheater and cement kiln to process clinker. Grate cooler helps to cooler clinker, the cooled clinker is sent to the cement silo for storage.

More

GitHub

Mpf Coal Mill Vertical mills coal mill mpf 2217.vertical grinding milling machine food grade.mpf2417 vertical mill drawings vertical mills coal mill mpf 2217 geber pfeiffer vertical roller mill loesche layout amp.Contact supplier Shaking Table And Roller Coal Mills.Get Price; vertical roller mill design of Cement Plant Raw Mill In India Youtube ...

More

How to Start a Cement Factory Design Construction of Cement Plants

3. Design the Cement Factory. As a large-scale industrial facility with complex structures and numerous machinery, the design and layout of a cement plant must be entrusted to the professional engineering design institute. The design institute is the cooperative unit with the longest service time and the widest content for the project.

More

Application of ESP for gas cleaning in cement industry

2001.3.1 Particulate matter emission from a stack attached to the kiln and raw mill in a cement plant was studied. Elemental (As, Cd, Co, Cr, Cu, Fe, Mn, Ni, Pb and Zn) and ionic (Ca2+, NO3−, SO42− ...

More

Modeling of energy consumption factors for an industrial cement ...

2022.5.9 Cement production is one of the most energy-intensive manufacturing industries, and the milling circuit of cement plants consumes around 4% of a year's global electrical energy production. It is ...

More

Belt Bucket Elevator Chain Bucket Elevator

The bucket elevator produced by our company can be divided into ring chain bucket elevator (TH), plate chain bucket elevator (NE) and belt bucket elevator (TD) according to different traction modes. Ring chain bucket

More

Application of ESP for gas cleaning in cement industry

2001.2.16 Electrostatic precipitators (ESP) are used for gas cleaning in almost every section of cement manufacture. Application of ESP is studied, keeping in view Indian conditions. The characterisation of dust emissions has been done for different units, such as rotary kiln and raw mill, alkali by-pass, clinker cooler, cement and coal mill, in terms of ...

More

Cement Division - thyssenkrupp Industries India

thyssenkrupp Industries India (tkII), has built cement plants that are fuel and energy efficient and also environment friendly. Its sustained success in winning repeated new orders has established it as one of the leading cement plant making companies in India. tkII has designed, manufactured, supplied, installed and commissioned large capacity ...

More

Full article: Evaluation of optimization techniques for

2021.7.5 The cement raw mill is the primary piece of equipment used in the modern cement industry for the raw meal production process. As a result, it is critical to investigate the exergy efficiency in a cement raw mill in order to satisfy the need for the design and optimization of the cement plant manufacturing process.

More

Industrial plants - factories on AutoCAD 765 free CAD blocks

765 Industrial plants - factories CAD blocks for free download DWG AutoCAD, RVT Revit, SKP Sketchup and other CAD software.

More

(PDF) Engineering Design of Mechanical Equipment for the

2017.5.1 For fine grinding of cement clinker and additives, ball mills of various sizes are mostly used [1,2,6,7]. These grinding units are distinguished by the simplicity of their design, its operation ...

More

sbm/sbm drawings of stone crushing plants.md at master

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

More

Development Trend Analysis of Cement Production Line

2023.11.21 The development trend of future cement production lines will mainly focus on innovation in design concepts and related equipment to meet the growing market demand and reduce negative impacts on the environment. In this article, we will introduce the development trends of cement production lines and explore their impact on the cement

More>> Next:Machine De Moulin Au Kenya

Article aléatoire

- quelle mine de fer en algerie

- serie smc moulin super mince

- mines de manganèse Maroc

- taille d une balle de 140 mesh broyage

- les minerai en algerie en France

- machine de fabrication de plaque doeufs en cartonplastique algerie

- jual concasseur de pierre mesin pemecah batu 250400 htm mobiles

- niveau de bruit de broyeur Indonésie béton

- équipement de concasseur Indonésie mâchoires

- entreprises de carrière dans le secteur minier de malaisie

- utiliser le mot carrière dans une phrase

- additifs dans la production de beton

- pieces Afrique concasseur de pierre ciros

- avantages et les inconvénients de concasseur à machoires concasseur giratoire à

- concasseur à cône indiadirectory concasseur machines

- charbon moulin problème de démarrage

- liste de la plante concasseur à haryana

- equipement de securite de la machine concasseur

- concassage et criblage dusines en calcaire